Ultra Performance Bridge Type Machining Center Kamioka DMC-2532

Online only

Kamioka DMC-2532

New product

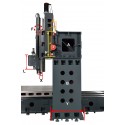

Ultra Performance Bridge Type Machining Center DMC-2532

|

FEATURES |

|

|

2-rail roller type linear guide plus another 2-rail ball linear guide ways on X-axis for high speed movement (applied to DMC-2532 and DMC-2542) |

A: Larger sectional area of beam B: Larger sectional area of column E: Step type linear ways mounting F: Z box way and counterweight system with twin hydraulic cylinder H: Larger span between guideways L: Without indirect transmission shaft X: The shortest center distance on X-axis Y: Larger width of machine column |

|

Powerful gear drive spindle with max. I.D. 100mm bearing |

Table, headstock, beam & machine base designed with multi-layer intensive ribs, which is excellent for heavy duty machining. |

|

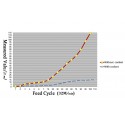

Coolant through axial ballscrew with high-resolution encoder to reduce the thermal elongation and enhance the positioning accuracy. |

|

|

Comparison between coolant through ballscrew and without cooling |

|

|

Extension Head (Manual Head Attachment without Indexing, max. 2000rpm) |

30-degree Milling Head (Manual Head Attachment with Manual Indexing, max. 2000rpm) |

|

90-degree Milling Head (Manual Head Attachment with Manual Indexing, max. 2000rpm) |

Universal Head (Manual Head Attachment with Manual Indexing, max. 2000rpm) |

|

Item/Model No. |

Unit |

DMC-2532 |

|

Travel |

||

|

X/Y/Z |

mm (in.) |

3,200/2,700/900 (125.98/106.3/35.43) |

|

Z axis-Optional |

mm (in.) |

1,100 (43.31) |

|

Distance between Columns |

mm (in.) |

2,500 (98.43) |

|

Table |

||

|

Dimension |

mm (in.) |

3,000×2,100 (118.11×82.68) |

|

T-slot (W×No.×CD) |

mm |

28×10×200 |

|

Max. Table Loading |

kg (lb.) |

12,000 (26,400) |

|

Spindle |

||

|

Max. Speed-Standard |

rpm |

Gear drive 6,000 |

|

Max. Speed-Optional |

rpm |

Direct drive 10,000 |

|

Spindle Motor |

kW (HP) |

22/26 (29/35) |

|

Spindle Taper |

BT50 |

|

|

Spindle Nose to Table Surface |

mm (in.) |

200~1,100 (7.87~43.31) |

|

Feedrate |

||

|

Cutting Feedrate |

mm/min (ipm) |

1~10,000 (0.04~393.7) |

|

X axis Rapid Traverse |

mm/min (ipm) |

18,000 (708.66) |

|

Y axis Rapid Traverse |

mm/min (ipm) |

18,000 (708.66) |

|

Z axis Rapid Traverse |

mm/min (ipm) |

15,000 (590.55) |

|

ATC |

||

|

Tools Capacity-Standard |

pcs |

Swing Arm 24 |

|

Tools Capacity-Optional |

pcs |

Chain 32, 40, 60 |

|

Max. Tool Dia. |

mm (in.) |

ø127 (ø5) / ø215 (ø8.46) without adjancent tools |

|

Max. Tool Length |

mm (in.) |

300 (11.81) |

|

Max. Tool Weight |

kg (lb.) |

20 (44) |

|

General Information |

||

|

Electrical Power Capacity |

KVA |

60 |

|

Dimension (W×D×H) |

mm (in.) |

6,000×9,000×4,500 (236.22×354.33×177.17) |

|

Machinery Weight (Net) |

kg (lb.) |

34,000 (74,800) |

|

|

|

|

- STANDARD EQUIPMENT

1.Semi-enclosed Splash Guard (without Roof)

2.2-step Gear-drive 6000rpm Spindle

3.Roller Linear Guide Ways on Three Axes or X, Y Roller Linear Guide Ways with Z Box Guide Way

4.Telescopic Cover (Bellow) on Three Axes

5.Coolant Through Axial Screws

6.Cutting Coolant Unit

7.Auto Lubrication System

8.Air Blast Through Spindle Taper

9.Air Blow

10.Heat Exchanger in Electric Cabinet

11.Spindle Oil Chiller

12.Counterweight System with Twin Hydraulic Cylinder

13.Encoder Feedback Device on X-axis

14.Hinge Type Chip Conveyor & Bucket

15.Coolant Tank

16.Arm Type Operation Panel

17.Foot Switch for Tool Unclamping

18.LED Lamp & Alarm Indicator

19.Service Tools & Leveling Bolts

20.Movable Manual Pulse Generator (Hand-wheel)

21.Mechanical & Electrical Operation Manuals

22.Precision Check Data

- OPTIONAL ACCESSORIES

1.D.D.S 10000rpm Spindle

2.32 pieces Tool Capacity of Magazine

3.40 pieces Tool Capacity of Magazine

4.60 pieces Tool Capacity of Magazine

5.Air Conditioner in Electric Cabinet

6.Sub Working-table

7.Raised on Height of Column

8.Linear Scales

9.Full Enclosure Splash Guard with Roof

10.Swing Type Operation Panel (Movable in Horizontal Direction)

11.Swing Type Operation Panel (Movable in Five-face Direction)

12.Manual Clamping Heads: 30-degree, 90-degree, Extension and Universal Head

13.Auto Clamping Head: 30-degree, 90-degree, Extension and Universal Head

14.4th Axis Rotary Table

15.Coolant Through Spindle

16.Coolant Through Tool Holder

17.Oil Skimmer

18.Oil Mist Collector

19.Tool Setting Probe

20.Workpiece Measurement

21.Transformer

22.Door Interlock

23.CE