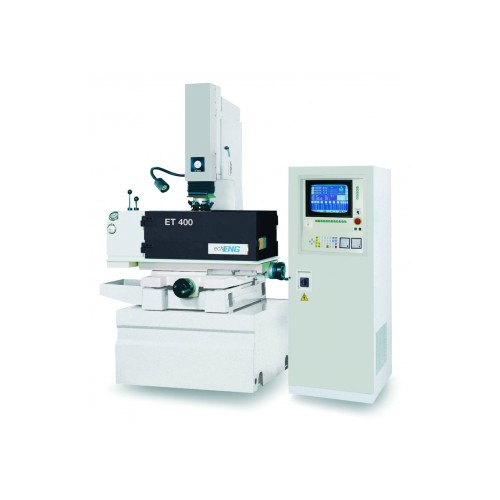

Electrical discharge machine Echord ET 400 CNC

- Rigid frame in high tensile annealed meehanite cast iron

- X-Y-Z axes with servo motors

- High precision V roller guides and ball screws.

Online only

Echord ET 400 CNC

New product

ET 400 CNC

Description

- Rigid frame in high tensile annealed meehanite cast iron

- X-Y-Z axes with servo motors

- High precision V roller guides and ball screws.

- 3 safety equipment: infra-red sensor, oil temperature sensor, automatic extinguisher

- Automatic discharge time regulator

- 3D or orbital machining

- X-Y-Z axis with automatic part probing, internal bore or slot probing, external probing function of a cylindrical or rectangular piece and automatic edge probing.

STANDARD EQUIPMENT

- 15” LCD Monitor;

- Auto fire extinguesher;

- Work lamp low voltage;

- Clamping plate;

- Levelling pad;

- Flushing nozzle;

- Patented electrode holder;

- Paper filter;

- Drill chuck;

- Signal tower light;

- M.P.G.;

- Remote controller;

- Service wrenches and user’s manual.

TEChNICAL DATA

|

CHARACTERISTIC

|

UOM

|

VALUE

|

|---|---|---|

|

Table travel X

|

mm

|

400

|

|

Table travel Y

|

mm

|

300

|

|

Table travel Z

|

mm

|

300

|

|

Precision axis X,Y,Z

|

mm

|

0,001

|

|

Work tank dimensions

|

mm

|

990x565x380

|

|

Table dimensions

|

mm

|

650x350

|

|

Maximum table-spindle nose distance

|

mm

|

160-590

|

|

Maximum electrode weight

|

kg

|

120

|

|

Maximum load on table

|

kg

|

700

|

|

Max current / power input

|

A/KVA

|

60/4.5

|

|

Max current / power input

|

A/KVA

|

90/8 (on request)

|

|

Max current / power input

|

A/KVA

|

120/12 (on request)

|

|

Best surface roughness

|

μm/ra

|

0.2

|

|

Dielectric tank capacity

|

l

|

357

|

|

Electrical supply

|

V/Hz

|

400/50 3 PH

|

|

Overall dimensions

|

mm

|

3815x1460x2240

|

|

Weight

|

kg

|

1350

|