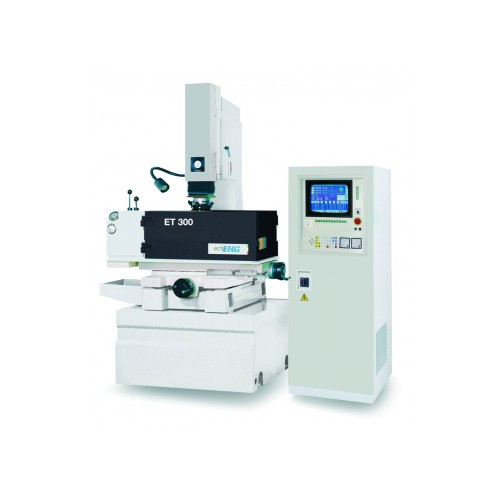

• Rigid frame in high tensile annealed meehanite cast iron

• X-Y-Z axes with servo motors

• High precision V roller guides and ball screws

• 3 safety equipment: infra-red sensor, oil temperature sensor, automatic extinguisher

• Automatic discharge time regulator

• 3D or orbital machining

• X-Y-Z axis with automatic part probing, internal bore or slot probing, external probing function of a cylindrical or rectangular piece and automatic edge probing.

Standard Accessories

15” LCD Monitor, auto fire extinguesher, work lamp low voltage, clamping plate, levelling pad, flushing nozzle, patented electrode holder, paper filter, drill chuck, signal tower light, M.P.G., remote controller, service wrenches and user’s manual.

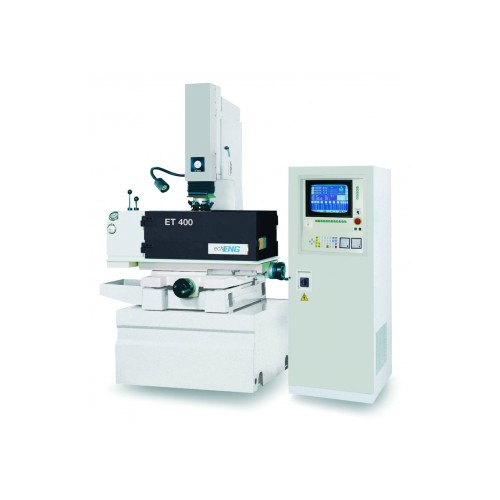

DATASHEET:

| um | value | |

|---|---|---|

| X axis travel | mm | 400 |

| Y axis travel | mm | 300 |

| Z axis travel | mm | 300 |

| Precision axis X,Y,Z | mm | 0.001 |

| Work tank dimensions | mm | 990x565x380 |

| Table dimensions | mm | 650x350 |

| Maximum table-spindle nose distance | mm | 160-590 |

| Maximum electrode weight | kg | 120 |

| Maximum load on table | kg | 700 |

| Max current / power input | A/KW | 60/4,5 |

| Best surface roughness | μm/ra | 0.2 |

| Dielectric tank capacity | l | 357 |

| Electrical supply | V/Hz | 400/50 3 PH |

| Overall dimensions | mm | 3815x1460x2240 |

| Weight | kg | 1350 |