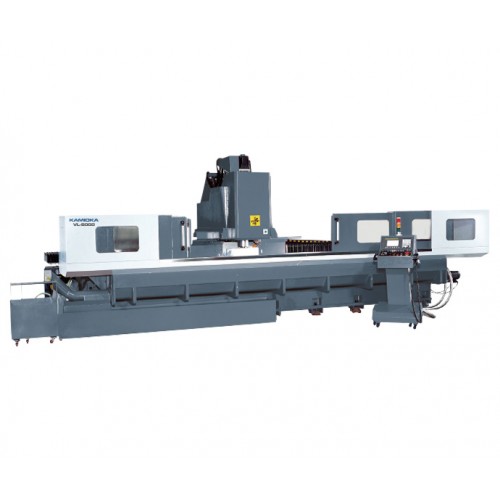

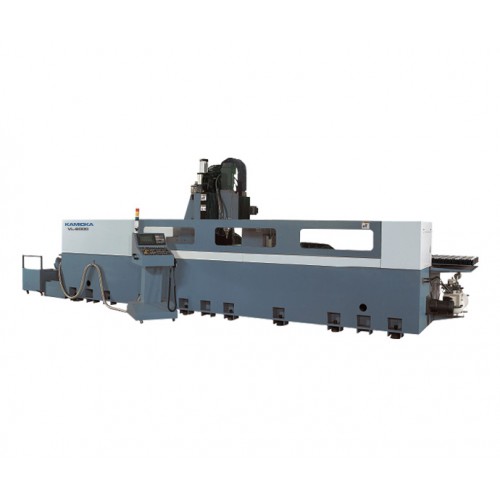

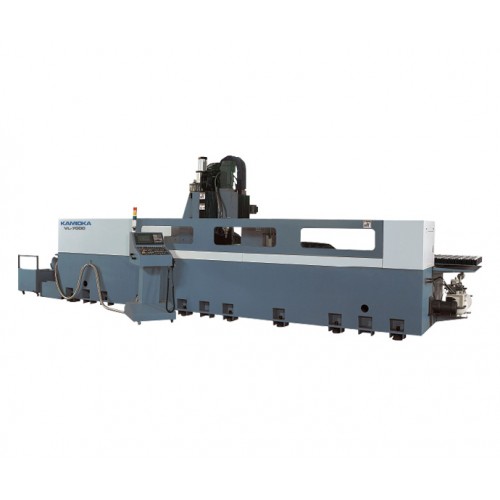

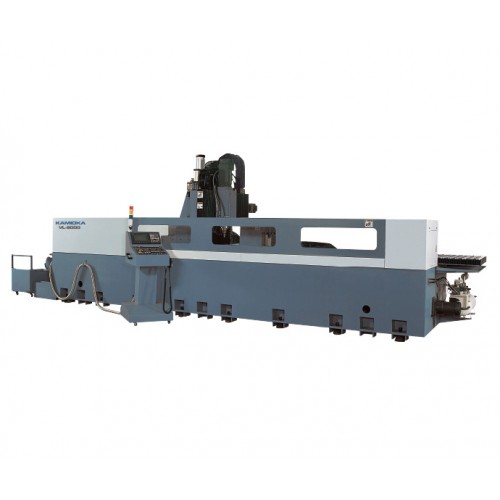

High Speed Vertical Machining Center Kamioka FORMULA TMC-500

High Speed Vertical Machining Center FORMULA TMC-500

Online only

TMC-500

New product

| FEATURES | |

|

|

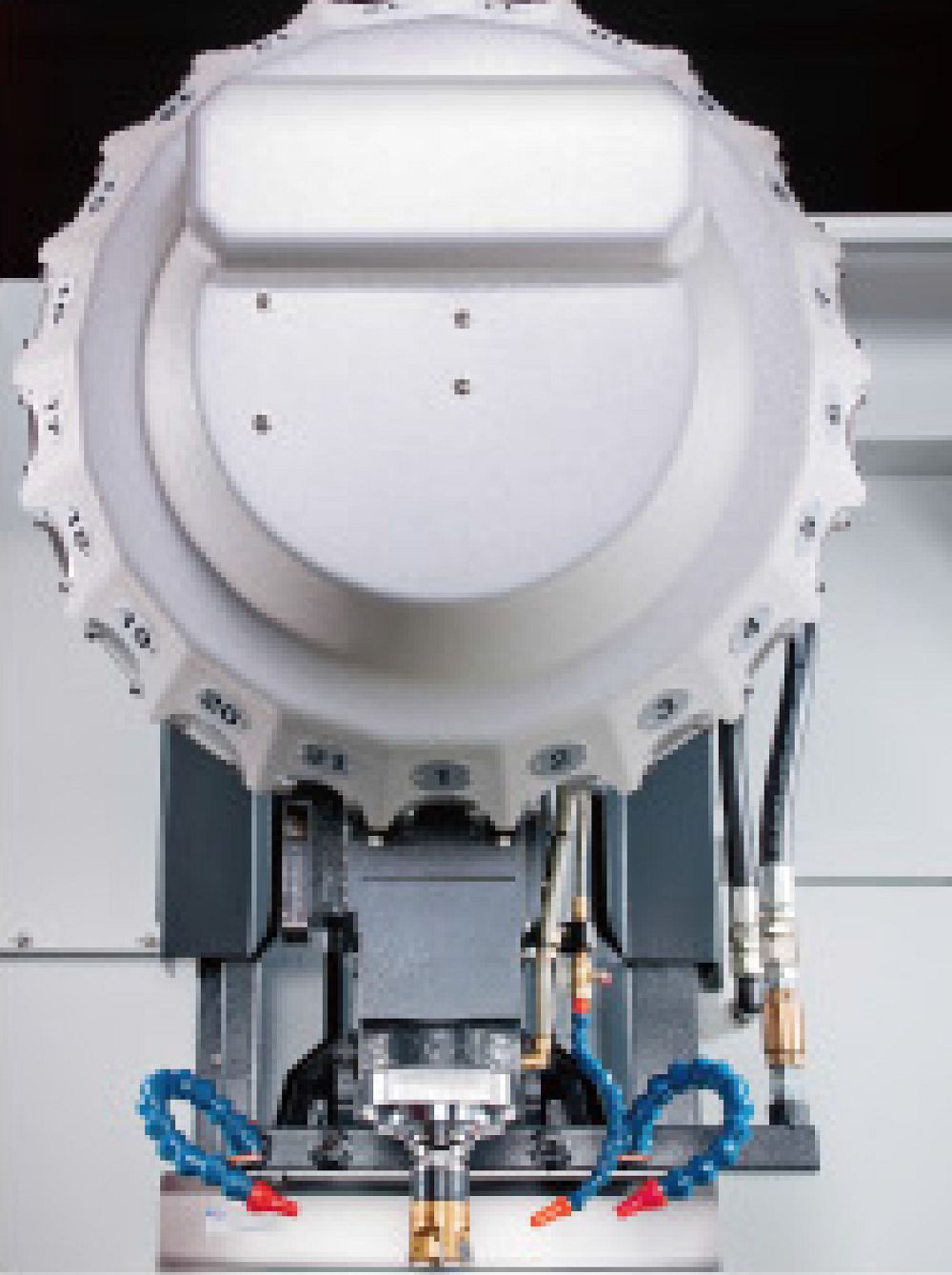

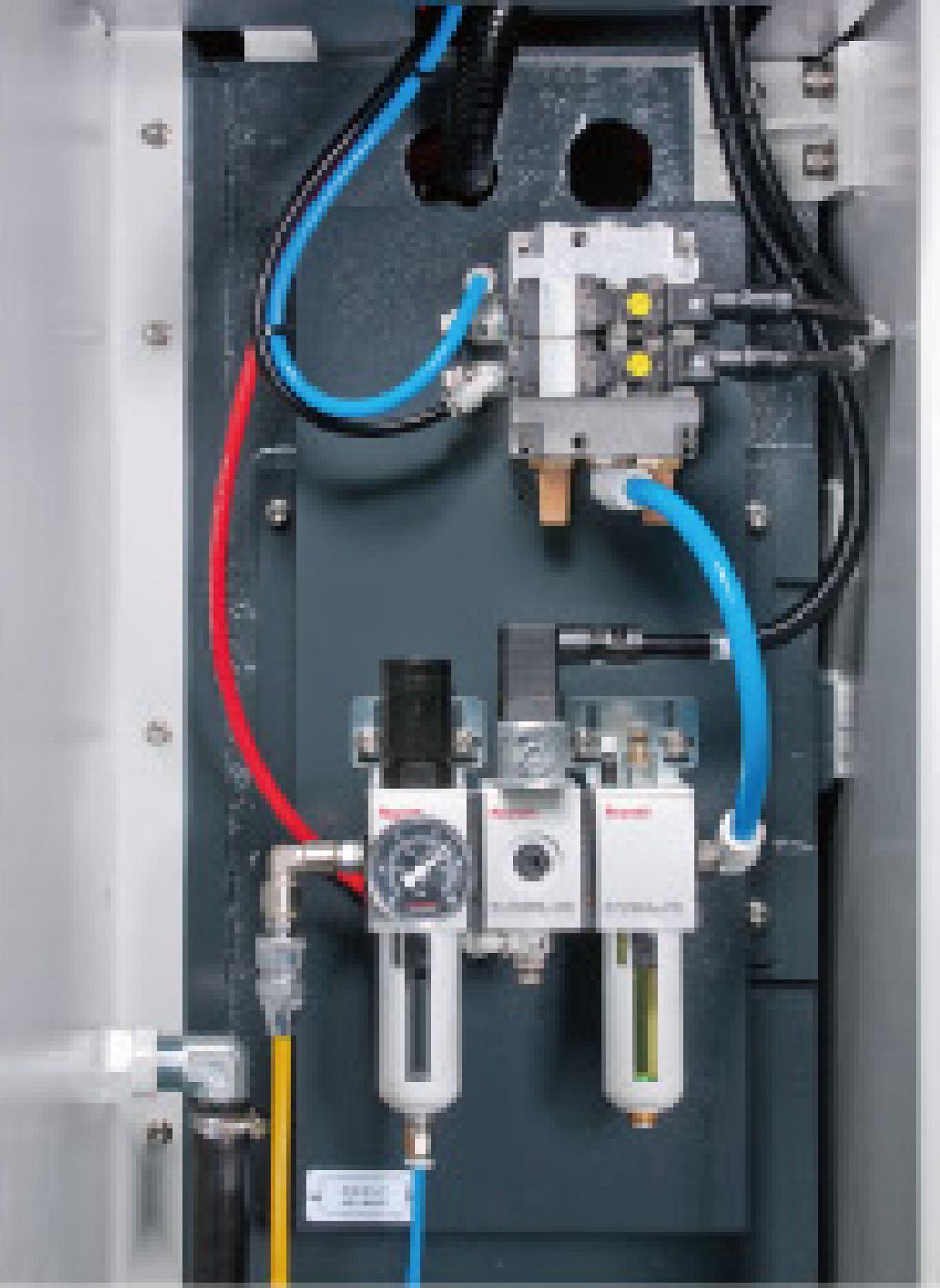

| 16 pieces clamp type auto tool changer, its body is manufactured from aluminum alloy for reducing the inertia load. | These pneumatic parts are centralized in an enclosed compartment to prevent them from bumping. |

|

- |

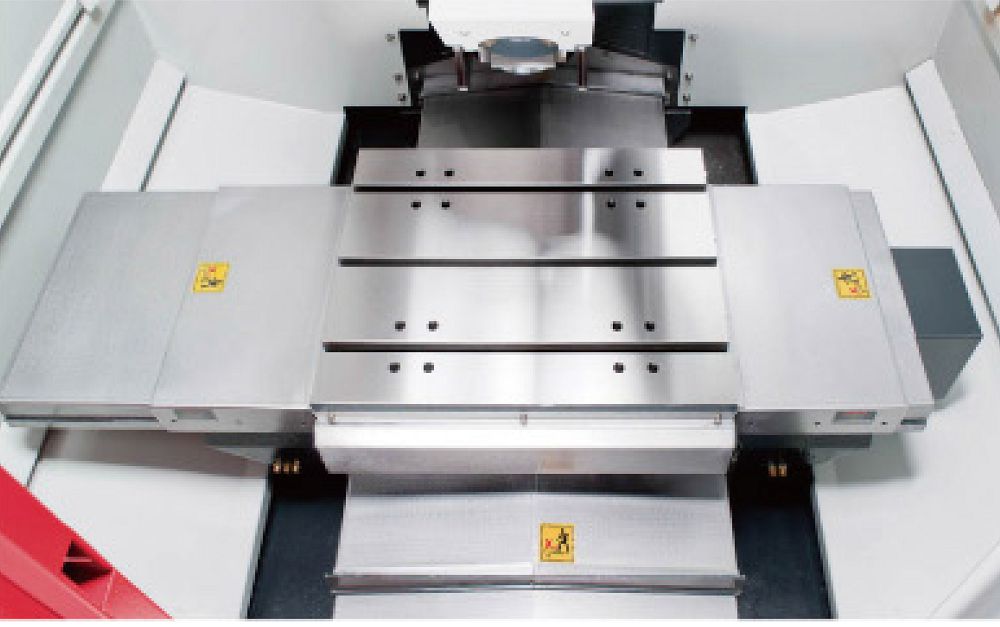

| Wide interior space features good ventilation, efficient chip evacuation. Two coolant flush motors are standard, equipped with the coolant flushing rings for removing heat source from the machine. | - |

| Item/Model No. | Unit | TMC-500 |

| Travel | ||

| X/Y/Z | mm (in.) | 500/400/300 (19.69/15.75/11.81) |

| Z axis-Optional | mm (in.) | - |

| Distance between Columns | mm (in.) | - |

| Table | ||

| Dimension | mm (in.) | 550×400 (21.65×15.75) |

| T-slot (W×No.×CD) | mm | 14×3×125 |

| Max. Table Loading | kg (lb.) | 250 (550) |

| Spindle | ||

| Max. Speed-Standard | rpm | Direct drive 12,000 |

| Max. Speed-Optional | rpm | Direct drive 15,000 |

| Spindle Motor | kW (HP) | M: 3.7/5.5 (5/7) |

| Spindle Taper | BT30 | |

| Spindle Nose to Table Surface | mm (in.) | 150~590 (5.91~23.23) |

| Spindle Center to Column | mm (in.) | 470 (18.5) |

| Feedrate | ||

| Cutting Feedrate | mm/min (ipm) | 1~12,000 (0.04~472.44) |

| X axis Rapid Traverse | mm/min (ipm) | 48,000 (1889.76) |

| Y axis Rapid Traverse | mm/min (ipm) | 48,000 (1889.76) |

| Z axis Rapid Traverse | mm/min(ipm) | 48,000 (1889.76) |

| ATC | ||

| Tools Capacity-Standard | pcs | Turret 16 |

| Tools Capacity-Optional | pcs | - |

| Max. Tool Dia. | mm (in.) | ø80 (ø3.15) |

| Max. Tool Length | mm (in.) | 200 (7.87) |

| Max. Tool Weight | kg (lb.) | 3 (6.6) |

| General Information | ||

| Electrical Power Capacity | KVA | 15 |

| Dimension (W×D×H) | mm (in.) | 1,650×2,600×2,450 (64.96×102.36×96.46) |

| Machinery Weight (Net) | kg (lb.) | 2,850 (6,270) |

●STANDARD EQUIPMENT

1.Full Enclosure Splash Guard

2.Linear Guide Ways on Three Axes

3.Telescopic Cover (Bellow) on Three Axes

4.Cutting Coolant Unit

5.Auto Lubrication System

6.Air Blast Through Spindle Taper

7.Air Blow

8.Heat Exchanger in Electric Cabinet

9.Spiral Type Chip Conveyor & Bucket

10.Servo Brake System on Z-axis

11.Coolant Tank

12.High Pressure Coolant Gun

13.LED Lamp & Alarm Indicator

14.Service Tools & Leveling Bolts

15.Manual Pulse Generator (Hand-wheel)

16.Mechanical & Electrical Operation Manuals

17.Precision Check Data

●OPTIONAL ACCESSORIES

1.D.D.S 15000rpm Spindle

2.Spindle Oil Chiller

3.Air Conditioner in Electric Cabinet

4.Hinge Type Chip Conveyor

5.4th Axis Preparation

6.4th Axis Rotary Table

7.Coolant Flush System

8.Oil Mist Collector

9.Tool Setting Probe

10.Workpiece Measurement

11.Transformer

12.Door Interlock

13.CE