• Accurate positioning and repetability performance of synchronized CNC brakes

• Calibration of cylinder axes and back gauge axes, maintained by automatic indexing at the start of machine

• Calculation and performing of below facilities: - determination of bending force necessary of bending stroke - Inspection on display, of potential interference between machine, tools and parts before and after each bend - automatic positioning of the backgauge for each step of the bending program - calculation of bottom and top dead centre for accurate bending a - storage and recalling of bending tools - programming of bending speeds - selection of manual, semi-automatic and automatic working modes

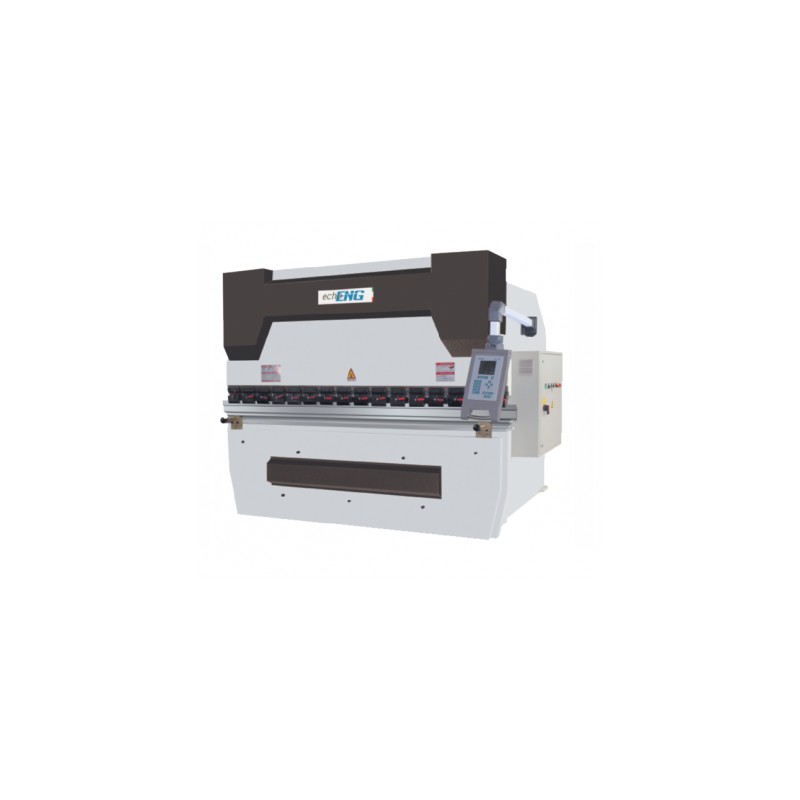

• Welded steel construction of monobloc frame

• Bend performing by down strocking beam

• Cylinders made from high quality forged steel

• Pistons hardened, chrome plated and ground precisely

• Hardened ram slideways working with low friction and wear resistant material and optimum lubrication grooves

• CNC controlled backgauge with ballscrews spindles, ball guides and AC or DC servomotors

• Compact Rexroth hydraulic blocks

• Full electronic synchronization with proportional valve technology.

Standard Accessories

• Control of the following 4 axes: Y1, Y2, X, R

• Delem DA51, DA64, Delem DA65W or Cybelec DNC 80, DNC800 graphical control units

• Backgauge system with X and R axes driven by AC indramat drivers and servo motors or linear guides

• Original CE conformed Bosch-Rexroth or Hoerbiger servo hydraulic systems with different types for different pressing capacities

• Manual bottom table anti deflection system for optimum bend angle precision throughout the full bending lenght

• Amada Promecam type tool hoding system

• Standard table with T channels and standard bottom tool clamping

• Ergonomic swinging control panel • Multi functional CE conformed foot pedal

• Two hand control system or front light barrier for the safety of the operators

• Side and rear safety guards and safety interock switches according to CE safety regulations

• Backgauge positioning fingers move along linear bearings with ± 0,01 mm. positioning tolerance

• Two laterally adjustable front support arms with slot for height adjustment and slot front stop.

DATASHEET:

| um | value | |

|---|---|---|

| Capacity | kN | 2500 |

| Bending lenght | mm | 3200 |

| Between columns | mm | 2540 |

| Throat depth | mm | 400 |

| Slide stroke | mm | 250 |

| Stroke adjustment | mm | 180 |

| Max. shut height | mm | 500 |

| Strokes per minutes | min-1 | ≥3 |

| Main motor power | kW | 18.5 |

| Electrical supply | V/Hz | 400/50 3 PH |

| Overall dimensions | mm | 3750×1970×2920 |

| Weight | kg | 13740 |